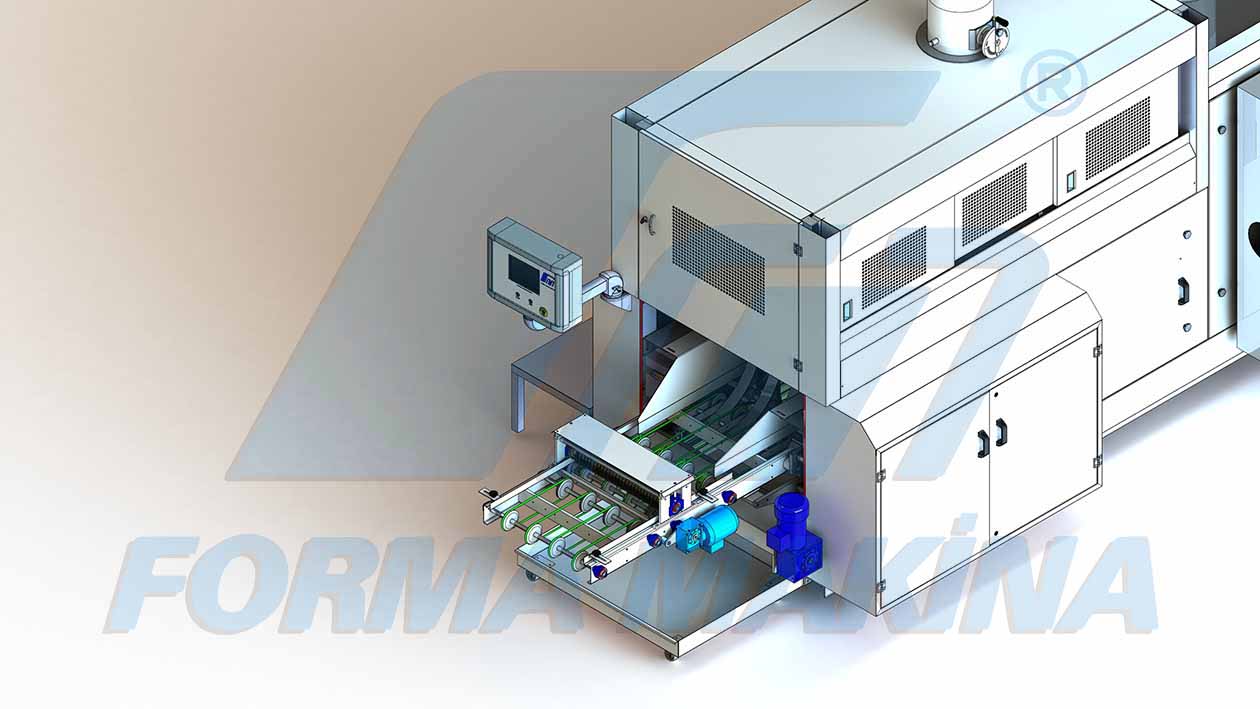

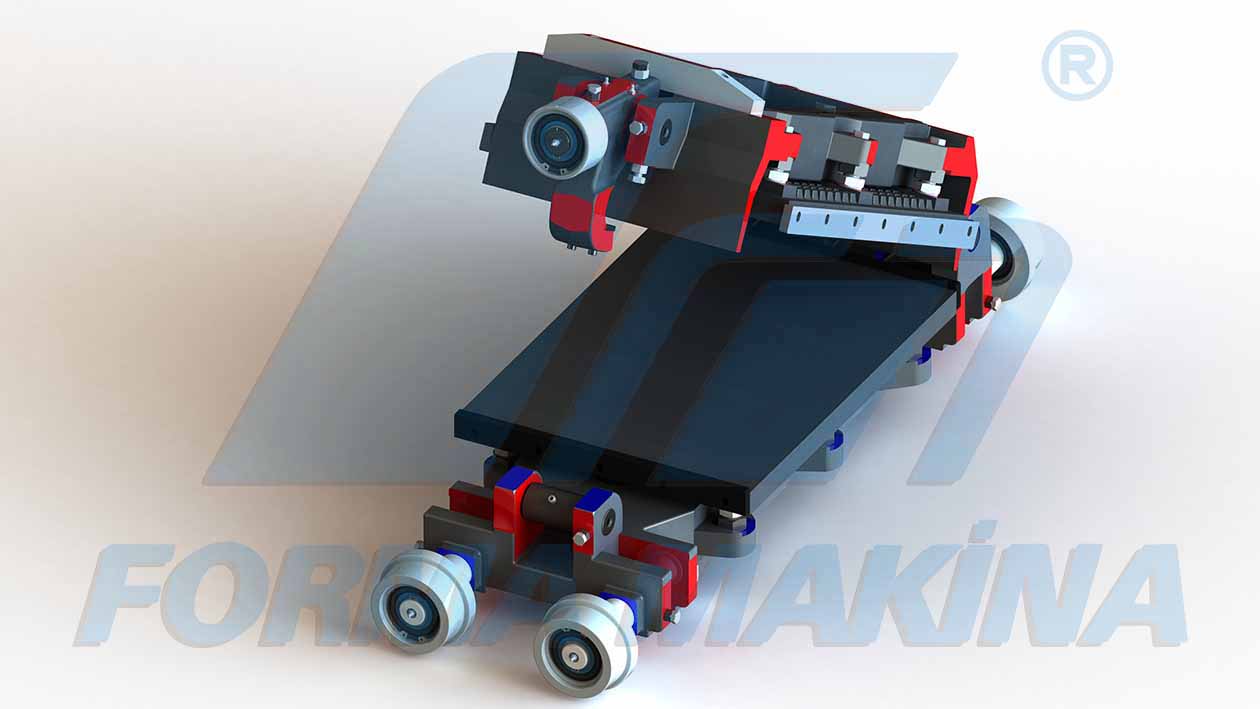

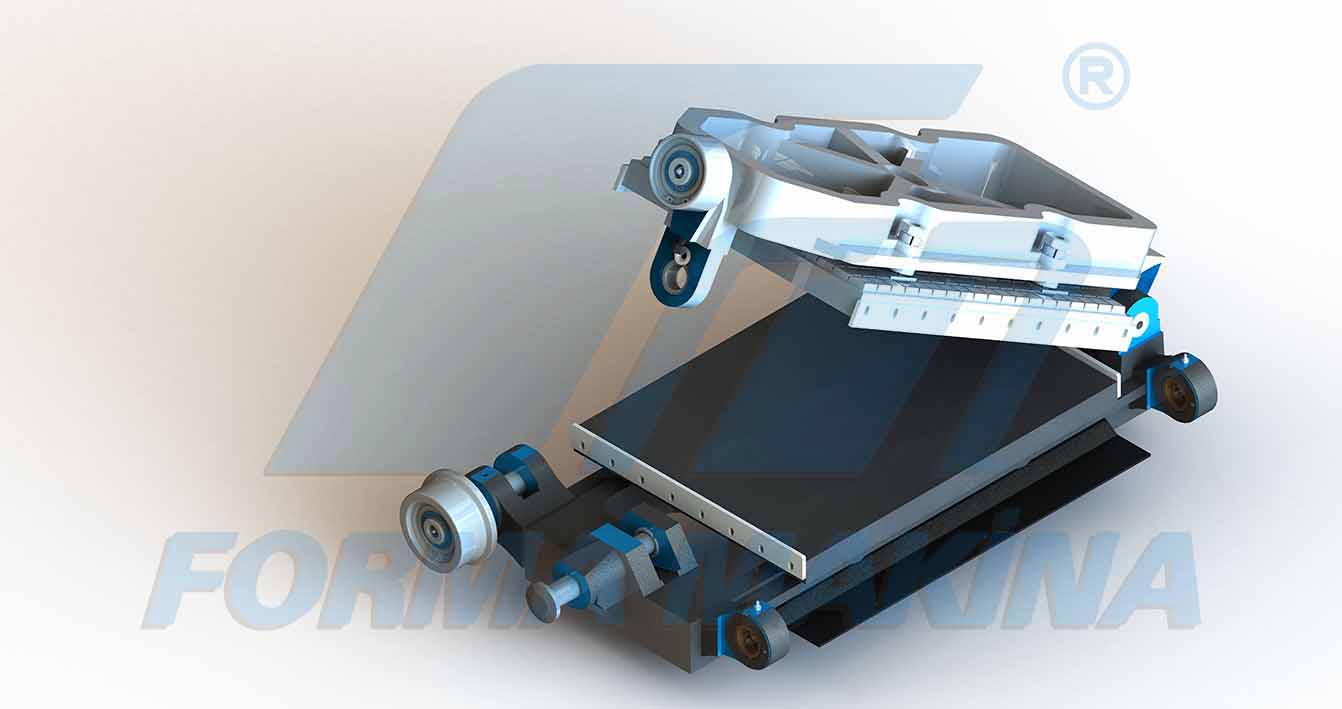

The wafer baking machine is used for the production of flat or hallow wafers. For wafers with a pattern of fine or medium reeding, the baking plates are designed as requested. The baking plates are either heated by natural gas, LPG or if requested, by electricity. The baking time can be infinitely adjusted between 1,5 and 5 minutes and depending of the recipe and weight of the wafer sheet is about 2 minutes. The system is equipped with energy saving burners. Each burner can be swiveled independent of the others which enables an optimum heat distribution over the whole baking surface. The entire heating system is ignited and monitored fully automatic. Oven is equipped with frequency controlled main drive, electronic control device for batter depositing with frequency controlled batter pump drive, automatic wafer sheet take-off system, automatic temperature control device, stainless steel enclosure, exhaust hood above the batter depositing station, automatic tensioning device for the baking tong chain, waste collecting bins, operating panel, control cabinet. BAKING TONGS The baking plates are supported by an extremely rugged and solid tong frame. This ensures that the thickness of the wafer sheet is kept constant over its entire surface. Each baking tong is equipped with four carriage rollers with thermally stabilised ball bearings. Baking plates are hard-chromed. BATTER DEPOSITING STATION WITH OPERATING PANEL Drop free batter depositing by means of dosing pump with frequency-controlled batter pump drive. Precisely positioned depositing by electronic batter depositing control device via input of the desired value on the operating panel. MAIN DRIVE, BAKING TONG CHAIN TENSIONING Infinitely variable baking time is controlled by means of frequency-controlled three phase drive. Baking tong chain tensioning is separately adjustable on right and left side; pneumatically actuated for automatic compensation of alterations in the baking tong chain length resulting from heating-up or cooling down procedures respectively. GAS MIXING UNIT Temperature control system of baking plates by frequency-controlled primary air fan. |